We are committed to giving V12 wearers the high-performing safety footwear they've come to expect – but whilst also striving for environmentally sound manufacturing in our products’ life cycle in every phase - starting with design, right through to shipping and packaging. So what are we doing and what are we going to do to be the most sustainable business we can possibly be?

.png?width=325&height=325&name=MicrosoftTeams-image%20(12).png)

We are thrilled to announce that we've been certified ZeroCarbon® by The Sustainable Future Group. This certification is the result of a company-wide drive to reduce our carbon footprint and make our production processes cleaner and greener, and we have a huge sense of achievement now we've hit this environmental goal.

George Turner, Managing Director

Find out the full story behind how we become a carbon neutral company here.

We're moving production from the Far East to Europe. Some styles have already moved, and there are more to come soon. Find out about it here.

A few of the many smaller changes we're making include introducing LED lighting and ensuring no plastic strapping is used in our packaging. We use no glue in our boxes or cartons, so our packaging process is vegan-friendly.

We use recycled and fully recyclable mailing bags and recycled cartons.

Our Lynx range is officially our most sustainable boot ever, which now includes the 100% recyclable Sympatex waterproof lining.

MukGuard means no more single-use plastic boot-covers. Explore here.

Our European-made footwear is made at LWG-certified tanneries - find out more about the LWG here.

Learn how we’re aiming for the highest standards of ethical trading here.

We use AI to help people find their correct fit first time, reducing the amount of shipping journeys and the resulting carbon emissions which occur when items are returned. Want to find out more? Click here.

We use industry-leading 3D sampling technology at the design stage, enabling us to be highly accurate at the manufacturing stage, which vastly reduces leftover material.

Read our informative and eye-opening blogs to find out everything you need to know.

There are more blogs on sustainability available – search ‘sustainability’ in our blog homepage to keep learning!

Climate change is the rise in global temperatures particularly from the industrial age to the present day. This warming of the planet has been caused by human activity that has put more gases such as carbon dioxide in the air, mostly due to the burning of fossil fuels for energy.

Fossil fuels are made from decomposing plants and animals. These fuels are found by mining the Earth's crust and contain carbon and hydrogen, and this is what is burned for energy. Coal, oil, and gas are examples of fossil fuels.

Carbon dioxide is a greenhouse gas – this means it’s a type of gas that traps heat and then radiates it back out. So, when too much is released into the atmosphere, it makes the earth hotter.

This situation of the planet getting warmer due to the burning of fossil fuels is now considered so extreme that many people have started using the term ‘climate crisis’ rather than climate change.

The earth’s increasing temperature has raised water levels by melting the world’s glaciers and ice sheets. This means there is a very high probability that a huge number of people soon won’t be able to live in their current locations, because their homes will be underwater, or their environment will be simply too hot to live in.

If a business is carbon neutral, it means whatever carbon emissions they put into the atmosphere are balanced out by what they remove from it, most commonly from carbon compensation. In simple terms, whatever 'bad' things are emitted in production, steps are taken to put an equivalent amount of 'good' things back into the environment.

Note - a product can be carbon neutral within a range of products which aren't carbon neutral. Similarly, a section of a company's supply chain might be carbon neutral whereas as other parts of that division of labour might not.

Carbon neutrality can apply to something as small as a one-person business, or it can be assigned to large companies with a global reach.

Net zero is often used interchangeably with carbon neutral, but there is one key difference: net zero is a measurement of total emissions, not just carbon.

So, if a business was to achieve net zero, it would balance not just its carbon output with its reductions, but also any other emissions it was responsible for, such as methane, nitrous oxide or any gases with GWP (Global warming potential).

Carbon offsetting is a process that involves a reduction in or removal of carbon dioxide or other greenhouse gases to compensate for emissions made elsewhere.

Carbon offsetting takes many forms. For example, a company can invest in ‘carbon credits’ which will enable them to plant a particular amount of trees which will eventually emit enough oxygen to counterbalance the GHSs used in the manufacturing of a certain product. Alternatively, businesses can invest in environmental regeneration schemes dedicated to rewilding or reforesting areas, or the construction of more renewable energy plants.

Scopes 1, 2 and 3 are all types of emissions. Whether they are described as scope 1, 2 or 3 depends on where these emissions originate from.

Renewable energy, often referred to as clean energy, comes from sources or processes that can be constantly and naturally replenished.

For example, sunlight and wind create energy, but they will keep shining and blowing and don’t require any burning for their energy to be utilised, so they are ‘clean.’

Virgin plastic is new, unused and therefore unrecycled plastic material created from gas or crude oil. Virgin plastic is, while some argue essential for manufacturing, not a sustainable material.

CO2 is the unit by which carbon emissions are measured. Importantly, this metric does not account for any other greenhouse gases. On the other hand, CO2e is a measurement of the total greenhouse gases emitted.

The circular economy is a production and consumption model which involves sharing, reusing, repairing and recycling existing materials and products. With this method, the life of products is extended. As a result, less waste is generated, and less fossil fuels are burnt to provide energy for new products.

'Cradle-to-grave' is a way for a product’s full impact on the planet to be assessed. It considers how the product has had an ecological impact at every stage of its life, from making then shipping the product and the cardboard used in its packaging, right back to the energy that was used in obtaining the raw materials, all the way up to assessing how long it will take for the product to decompose if or when it’s disposed of at landfill.

'Cradle-to-gate' is an assessment of a partial product life cycle from resource extraction (cradle) to the factory gate – essentially, before it is transported to the consumer.

Governments have at their disposal a large range of financial and political measures to support their nations in developing more energy-efficient and ecologically friendly processes.

These measures include introducing:

You can read more about the ways governments have pledged to tackle the climate crisis in this article.

“It's great to be part of a team so DEDICATED to working with world-RENOWNED consultants and accredited third parties so we can BE safety footwear sustainability LEADERS.”

Kayley Van As, Operations Coordinator

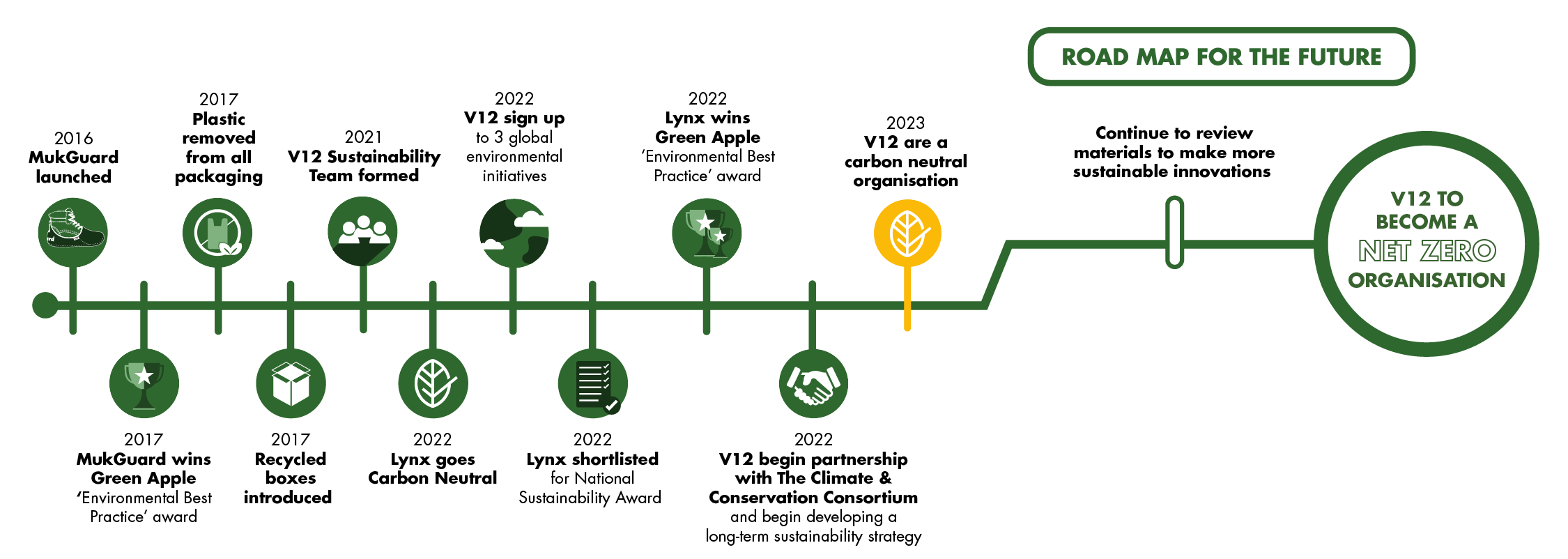

Sustainability at V12 has been a long journey so far – and it’s far from over. We continue to review and improve our sustainability practices to ensure that V12’s relationship with the planet is just like the one we have with our customers: long, healthy and harmonious.